Turnkey Services

Cleanrooms are key infrastructure in modern industrial production, pharmaceutical manufacturing and precision machining, and need to comply with international standards and specifications such as GMP/FDA and ISO 14644.

As a professional cleanroom manufacturer and cleanroom solution provider, Yaguan provides customers with cleanroom system design, construction and maintenance services through advanced technology and professional teams, ensuring that the production environment always meets relevant regulatory requirements.

- Home

- Turnkey Services

Our Services: Build Your High-quality Modular Cleanroom in 5 Steps

Follow our process to ensure your cleanroom is designed, built, and maintained with the highest industry standards: Compliant, Safe, and Tailored to Your Exact Needs.

Cleanroom Conceptual Design & Planning

- Feasibility analysis and requirements assessment

- Concept development aligned with GMP/FDA/ISO 14644 standards

- Preliminary specifications and budget planning

Detailed Engineering Design

- Complete cleanroom system design

- Critical parameter engineering calculations:

- Air change rates (ACH)

- Pressure design

- Temperature and humidity control parameters

- Particulate control specifications

- Specialized lighting requirements

- Contamination control strategies

Manufacturing

- Modular cleanroom component production

- Cleanroom wall/ceiling/floor systems

- HEPA/ULPA filtration units

- Air handling units (AHU)

Installation & Technical Support

- Installation assistance

- Maintenance support

Commissioning, Verification and Documents

- Comprehensive system testing and commissioning

- Complete qualification documentation:

- Design Qualification (DQ)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

Delivering Projects on Time, Within Budget, and Without Compromise

Shorten Project Cycle

Through detailed planning and prefabricated modular components, we can effectively reduce the complexity of cleanroom on-site construction, ensure on-time delivery and avoid project delays.

Budget Difficulty Control

Through accurate calculations and early procurement of key materials, we ensure that the project is always executed efficiently within the budget and avoid cost overruns.

Solve Technical Problems

With precise engineering calculations and standardized design processes, we ensure that the solution is highly reliable and minimizes late adjustments and additional costs.

We Provide Turnkey Services for

- Pharmaceutics industry

- Automotive industry

- Food Industry

- Beverage industry

- Micromechanics

- Genetic and Biological engineering

- Laboratories

- Microelectronics

- Medical devices

- Optoelectronics

- Nano-technology

Core Advantages of Our Modular Clean Room

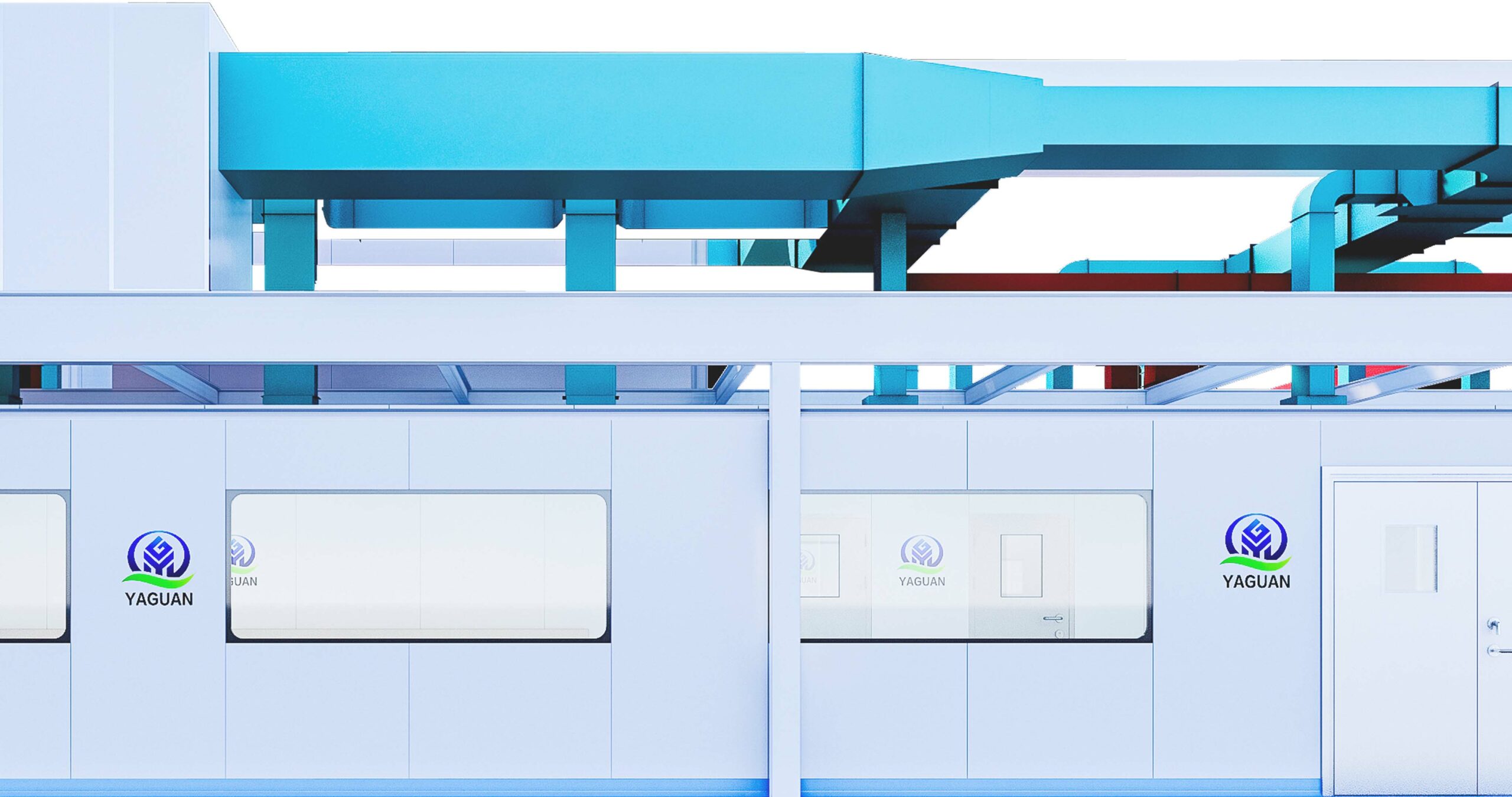

Leading HVAC Solutions

The HVAC system is the core of the cleanroom, determining comfort and cleanliness. We customize HVAC systems to your needs, using the latest prefabricated duct technology for efficient installation. Equipped with high-efficiency filters (HEPA or ULPA), our HVAC system effectively removes particles, bacteria, and chemicals, significantly enhancing cleanroom performance.

See How We've Delivered Excellence

prev

next

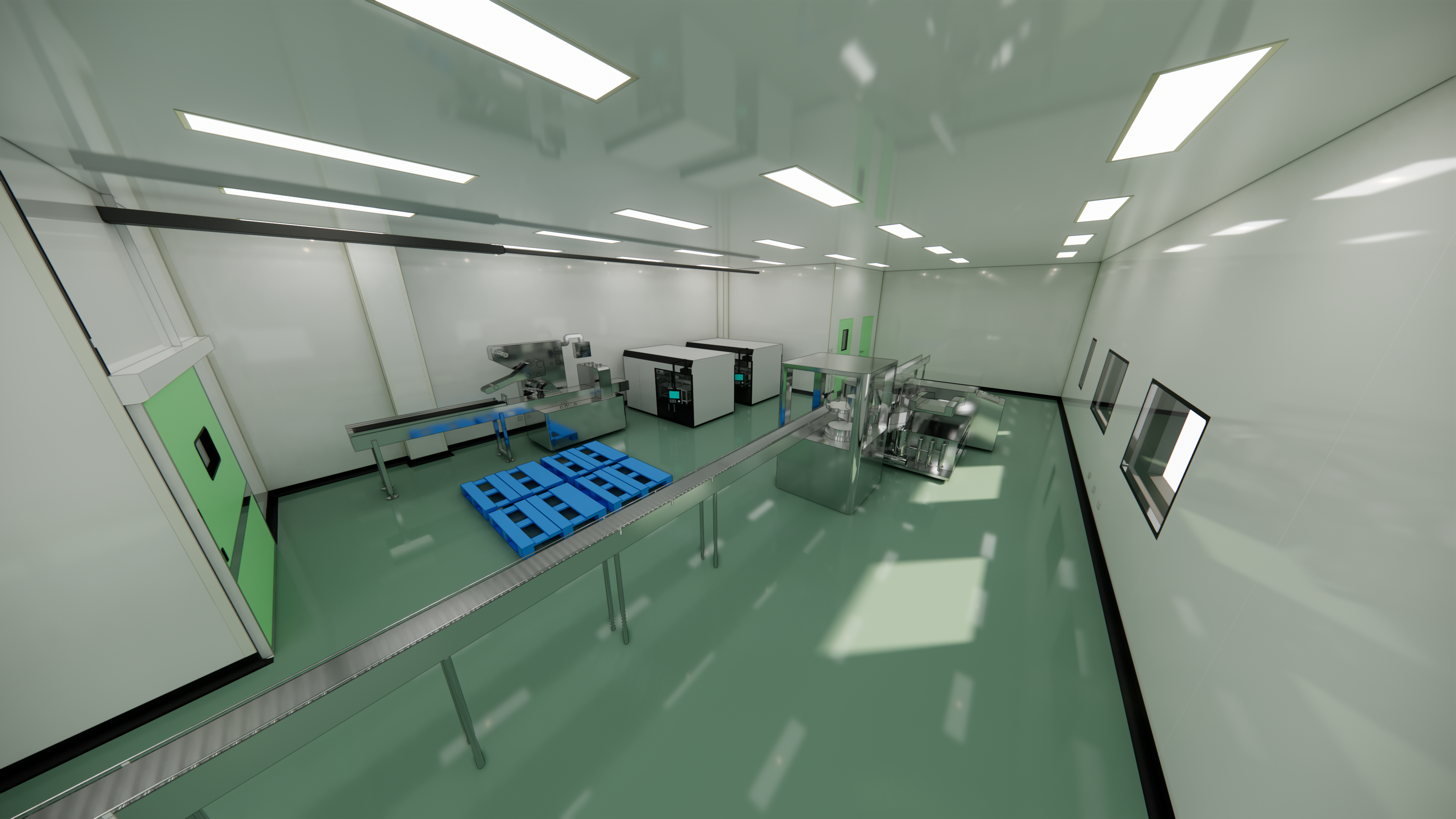

Experience Comprehensive Turnkey Cleanroom Solutions

Just tell us your requirements, and the rest will be fully visualized, including 2D/3D layouts, real-time production updates, expert installation guidance, and complete validation documents. Our goal is to ensure you can start using your cleanroom as soon as the door opens, worry-free.

Ready to Build Your Cleanroom?