Laminar flow ceilings, also known as unidirectional airflow ceiling systems, are critical components in modern cleanroom environments. Installed as terminal air supply units on the ceilings of controlled spaces such as operating rooms and cleanrooms, their primary function is to deliver a stable, uniform, and predominantly vertical downward stream of filtered air. This airflow pattern is based on the principle of laminar flow in fluid dynamics, wherein air particles move in parallel layers with minimal turbulence or lateral mixing. By maintaining this highly organized airflow, contaminants are effectively displaced from critical zones and removed via exhaust systems, thereby establishing and sustaining ultra-clean environments meeting or exceeding ISO Class 5 standards.

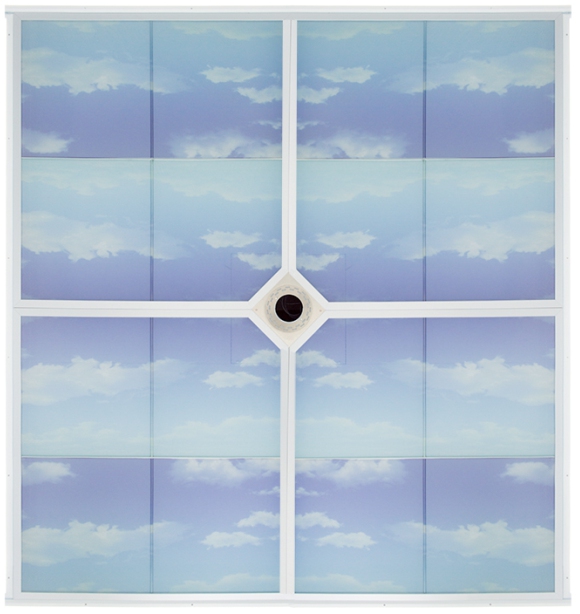

A complete laminar flow ceiling system comprises several precision-engineered components that operate in concert. The structural frame is typically constructed from stainless steel or powder-coated steel, providing mechanical stability and durability. The internal filtration assembly includes pre-filters followed by high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters, which ensure air purity through multi-stage filtration. Downstream of the filters, an air distribution device—such as a perforated plate or metal mesh panel—serves to homogenize the airflow, ensuring uniform velocity profiles across the discharge plane. The outer decorative panel not only enhances aesthetic integration but also protects internal components. Notably, HEPA filters achieve a minimum efficiency of 99.99% against 0.3μm particles, while ULPA filters demonstrate filtration efficiencies of up to 99.999% for particles as small as 0.12μm, satisfying the stringent cleanliness requirements of industries such as semiconductor manufacturing and pharmaceutical production.

Key performance metrics for evaluating laminar flow ceilings include the clean airflow coverage ratio and air velocity non-uniformity. The clean airflow coverage ratio refers to the proportion of effective air outlet area relative to the total supply surface area. According to China’ s national standard GB 50333-2013, this value must exceed 0.9 to eliminate airflow blind spots and ensure comprehensive contaminant removal. Air velocity non-uniformity quantifies the deviation of local velocities from the mean at a specified working height; for instance, in Class Ⅰ clean operating rooms, the allowable turbulence intensity (β) must not exceed 0.24. These two parameters collectively determine the system’s ability to establish a reliable, uninterrupted unidirectional airflow barrier.

Based on structural design, laminar flow ceilings are primarily categorized into three types. First is the leak-prevention type, featuring an innovative “leak-prevention layer” that decouples filtration, airflow equalization, and leakage control functions. This Chinese-developed technology ensures downstream airflow purity even in the event of upstream filter leakage, offering superior safety, enhanced airflow quality, and reduced sensitivity to installation tolerances. Second is the fan filter unit (FFU), a modular, self-contained system comprising integrated fans and filters. Multiple FFU can be assembled into a full-scale ceiling array, offering flexibility in layout and enabling safer negative-pressure operation. Third is the conventional full-array high-efficiency filter ceiling, which relies entirely on precise fabrication and sealing during installation to maintain airflow integrity, thus demanding exceptionally high manufacturing and commissioning standards.

From the standpoint of global standardization frameworks, laminar airflow ceiling systems are subject to well-defined regulatory requirements across various countries.

China’ s national standard, the Architectural Technical Code for Hospital Clean Operating Department (GB 50333-2013) mandates that centralized air supply devices in operating rooms should preferably be factory-fabricated, modular, and easy to install, minimizing on-site construction. It recommends the use of leak-prevention-type units and specifies that final-stage filter be located within adjacent technical floors. Furthermore, the standard requires that final filters should be replaceable from outside the operating room to prevent contamination during maintenance. For Class I operating rooms, the prescribed supply air velocity ranges between 0.20 – 0.25 m/s, with turbulence intensity limited to β ≤ 0.24, ensuring consistent airflow stability over the surgical field.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) has long advocated for high-performance filtration and laminar airflow strategies. ASHRAE Standard 170, Ventilation of Health Care Facilities, emphasizes performance-based verification, focusing on real-world operational outcomes. Its technical provisions require that the supply air coverage extend at least 305 mm beyond all edges of the operating table and specify a volumetric airflow rate of 457–640 m³/(h·m²). These quantitative benchmarks aim to establish a robust, contaminant-free zone above the surgical site, thereby mitigating particulate-related infection risks at their source.

Germany’ s approach to laminar flow ceiling design is distinguished by its rigor and attention to dynamic performance. DIN 1946-4, Ventilation and air conditioning – Part 4: Ventilation in buildings and rooms of health care, introduces the concept of ” dynamic protection”, emphasizing the system’ s resilience against disturbances caused by personnel movement, equipment heat release, and other intraoperative activities. To validate airflow integrity under realistic conditions, the standard mandates smoke visualization tests to confirm the persistence of unidirectional flow patterns, ensuring reliable protective performance during actual clinical operations.

Laminar flow ceilings are widely deployed across healthcare and advanced manufacturing sectors. In medical applications, they are essential in high-level operating rooms conducting complex procedures such as organ transplantation and joint replacement surgery. They also safeguard immunocompromised patients in bone marrow transplant units and burn care facilities, and serve as critical containment barriers in biosafety level 3 (BSL-3) and higher laboratories engaged in high-risk pathogen research. In high-precision industries, these systems are indispensable in semiconductor wafer fabrication, liquid crystal display (LCD) production, aerospace component manufacturing, and optical instrumentation, where even sub-micron particulates can compromise product yield or functionality. Additionally, they meet the stringent aseptic processing requirements for sterile drug filling and packaging in the pharmaceutical industry. Across all these domains, the common requirement is zero tolerance for airborne particulate contamination, making laminar flow ceilings a foundational technology for process reliability and patient or product safety.

Notably, the leak-prevention-type laminar ceiling developed in China represents a significant technological advancement. Its principle-based design fundamentally enhances long-term airflow cleanliness by isolating potential leakage paths, reducing dependence on exacting on-site installation practices. This architecture enables the formation of a more uniform, dense and low-turbulence displacement airflow, significantly improving both airflow quality and resistance to environmental disturbances. Moreover, its modular configuration reduces manufacturing precision demands and simplifies field installation, facilitating standardized production and rapid deployment. As a result, lifecycle costs are minimized, and engineering efficiency is enhanced. This innovation achieves a balanced improvement in safety, performance, and cost-effectiveness, positioning it as the preferred solution for the most demanding clean environments.

With ongoing technological advancements, laminar flow ceiling systems are evolving toward greater intelligence and energy efficiency. In the realm of smart monitoring, integration of IoT-enabled sensors allows real-time tracking of key operational parameters such as airflow velocity, pressure differential, and filter status. When combined with digital twin technology, these systems support predictive maintenance and dynamic performance optimization, significantly enhancing operational controllability. In material science, the adoption of advanced media such as nanofiber-based filters has improved filtration efficiency while reducing airflow resistance, contributing to lower energy consumption. From an energy management standpoint, the synergistic application of high-efficiency electronically commutated (EC) fans and computational fluid dynamics (CFD)-driven airflow modeling enables precise, energy-optimized system design. These innovations are transforming laminar flow ceilings from standalone air delivery units into integrated environmental control solutions.

As a cornerstone of clean environment technology, laminar flow ceilings deliver highly controlled, unidirectional airflow, providing the highest level of particulate control for critical medical and industrial processes. This reflects the modern pursuit of environmental perfection in sensitive applications. As global demand for cleaner, safer, and more reliable environments continues to grow, technical standards and implementation practices are becoming increasingly harmonized. In particular, China’ s independently developed leak-prevention technology has introduced a novel solution to longstanding safety challenges in traditional designs and has gained broad international recognition. Amid this evolution, global standards are converging, and Chinese technological contributions are gaining prominence on the world stage. Together, these trends are driving the continuous advancement of laminar flow ceiling technology, reinforcing its role as an indispensable enabler of human health and high-tech industrial progress.