-

TAILORED SOLUTIONS

EXPERT CLEANROOM EQUIPMENT MANUFACTURER

Our cleanroom solutions cover a range of basic cleanroom equipment to ensure that they are well compatible with the cleanroom system.

Our Quality Certification

Yaguan has the necessary certifications to manufacture high-level modular cleanrooms.

Plant Area

15000

m²

Employees

200

+

Years Experiences

10

+

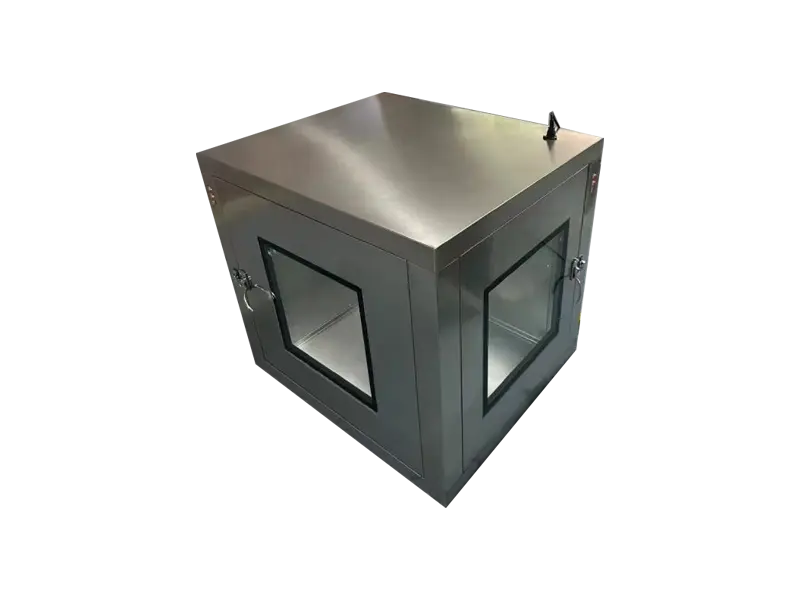

Explore Our Pass Box

Our High-Quality Pass-Through Window is designed for contamination-controlled environments such as cleanrooms, laboratories, pharmaceutical facilities, and food processing plants. It ensures safe, sterile material transfer between different zones while maintaining airflow integrity and particle control.

Dynamic Pass Box

Pass Box

Specifications

| Name | Inner Size mm W×D×H | Outer Size mm W×D×H 外尺寸 mm W×D×H | |||

| Static Pass Box | 500*500*500 | 660*560*600 | |||

| 600*600*600 | 760*660*700 | ||||

| 800*800*800 | 960*860*900 | ||||

| Dynamic Pass Box | 500*500*500 | 660*560*600 | |||

| 600*600*600 | 760*660*700 | ||||

| 800*800*800 | 960*860*900 |

Why Choose Our Pass Box: Unmatched Quality and Safety

Premium Material

Made of 304/316 stainless steel (anti-rust, easy to clean)

Interlocking Doors

Ensures only one door opens at a time to prevent cross-contamination

HEPA/ULPA Filtration (Optional)

Meets ISO Class 5-8 standards for ultra-clean transfer

UV Sterilization (Optional)

Eliminates microbes for higher safety in sterile environments

Smooth, Seamless Design

Compliant with GMP, FDA, and ISO 14644 requirements

Customizable Options

Available in different sizes (300x300mm to 1200x1200mm), manual/automatic operation, and embedded sensors.

Custom GMP Pass Box Solutions Across Diverse Industries

Pharmacy Clean Room

Modular Operation Theatre

Semiconductor Clean Room

Food & Beverage Clean Room

Aerospace Cleanroom

Our Core Service - Design & Build the Most Reliable Cleanroom

We collaborate closely with your team to design, build, and install top-quality cleanrooms. The more complex your project requirements, the more confident we are in leveraging our technical expertise to meet your needs.

How it works

- Consultation & Communication:

Our engineers listen carefully to your needs and provide expert consultation and technical support.

- Design:

Based on your layout, we conduct detailed designs for AHU cooling and heating loads, temperature, humidity, and cleanliness, while providing a synchronized quote.

- Proposal Confirmation & Production:

Once the design is finalized, production begins, we ensure all processes meet technical specifications.

- Delivery:

Products are shipped according to the production schedule, ensuring custom solutions are delivered within 45 days.

- Installation & Commissioning:

We provide full technical support to ensure the seamless installation and efficient operation of your cleanroom system.

Tailored HVAC Cleanroom System: The Foundation of Cleanroom Efficiency

Core Advantages of Our Modular Clean Room

Leading HVAC Solutions

The HVAC system is the core of the cleanroom, determining comfort and cleanliness. We customize HVAC systems to your needs, using the latest prefabricated duct technology for efficient installation. Equipped with high-efficiency filters (HEPA or ULPA), our HVAC system effectively removes particles, bacteria, and chemicals, significantly enhancing cleanroom performance.

Why Yaguan

Choose Us as Your GMP Modular Cleanroom Suppliers

Professional Design

Design based on 1:1 real layout, we provide precise AHU load, temperature, and humidity calculations, ensuring you stay informed of every detail.

Prefabrication

Each module is manufactured and labeled in our factory, allowing for installation by sequence, reducing complexity and enhancing efficiency.

Compliance Support

Compliance support for GMP, FDA, and ISO 14644 cleanroom standards with comprehensive DQ/IQ/OQ/PQ validation services.

Steady Lead Time

Whether for small or large-scale layouts, we consistently deliver on time. 100m² cleanroom delivered in 20 days, 500m² in 45 days, and we offer 1 year warranty for the whole system.

Advanced Technology Integration

Our cleanroom systems incorporate both smart temperature and humidity control technology, and advanced prefabricated HVAC ductwork solutions, meeting higher standards for cleanroom performance.

Positive Industry Reputation

Over the past 10 years, we’ve maintained a positive review rate of over 95%. Customer recognition is our driving force to build your next cleanroom with confidence.

@YAGUAN, All rights reserved. Powered by MML